-

-

COMPANY PROFILE

-

COMPANY PROFILE

-

COMPANY SERVICE

-

COMPANY SERVICE

-

-

-

OIL MAKING PROCESS

-

Cooking Oil Press Machine

-

Hydraulic Oil Press Machine

-

Oil Seeds Pretreatment Plant

-

Screw Oil Pressing Machine

-

Oil Solvent Extraction Plant

-

Oil Refining Plant

-

Edible Oil Dewaxing Plant

-

OIL PRODUCTION PLANT

-

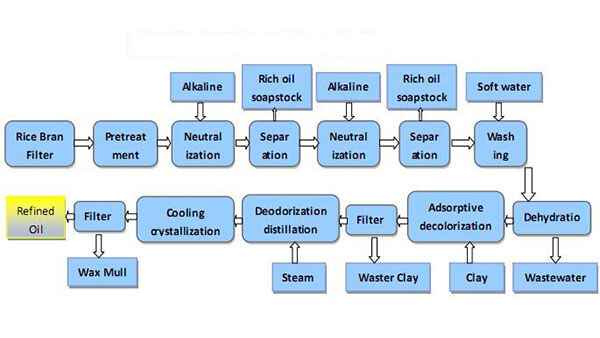

Rice bran Oil Production Plant

-

Soybean Oil Production Plant

-

Palm Oil Production Plant

-

Small Edible Oil Production Line

-

Peanut Oil Production Plant

-

Sunflower Oil Production Plant

-

Rapeseed Oil Production Plant

-

Cottonseed Oil Production Plant

-

Coconut Oil Production Plant

-

Oil Production Plant

-

OIL PRESS MACHINE

-

Peanut Oil Press Machine

-

Rapeseed Oil Press Machine

-

Sunflower Oil Press Machine

-

Soybean Oil Press Machine

-

Sesame Oil Press Machine

-

Castor Oil Press Machine

-

Corn Oil Press Machine

-

Cottonseed Oil Press Machine

-

Coconut Oil Press Machine

-

Palm Oil Press Machine

-

Related Products

-

Electric motor

-

Reducer

-

Pump

-

Boiler

-

Valve

-

Inverter generator diesel

-