Palm oil extraction plant

palm fruit/bunch → sterilization → threshing → press → clarification → purification →CPO→decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

1. Palm fruit reception:

Transport FFB to reception station, flow to the scraper conveyer, conveyed to sterilizing station.

2. Sterilizaiton:

FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145°C.

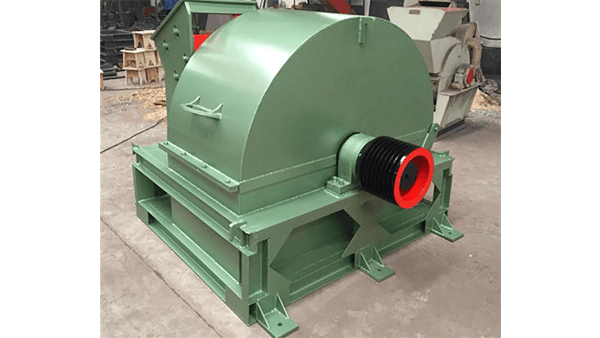

3.Threshing:

After sterilizing, fruit bunch transported to thresh machine, separate palm fruit and empty fruit bunch.

4.Digesting:

Before press palm fruit, should be crushed separated pulp and kernel.

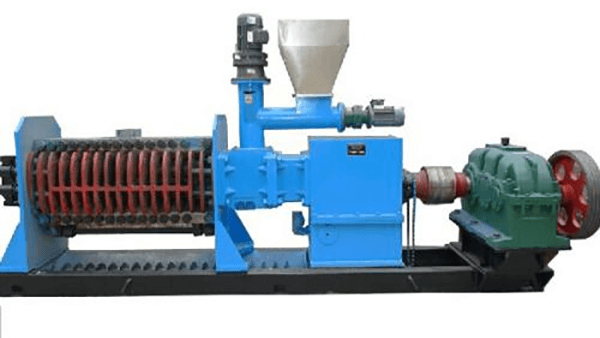

5.Oil press:

After crushing and digesting, the maxture of palm fruit and kernel fall into special palm oil presser

6.Clarification:

Filter the oil and use centrifuge to separate oil and impurities.

7.Kernel recovery:

After press, the kernel and cake will be transported to kernel recovery station. Separating nut and shell, then go to kernel oil press.

8. CPO Refining Processes

De-mixed,degumming, dehydration, deacidification, decolorzation, dewaxing and deodorization.

(1) Degumming :Usded to neutrilizing ,and water washing,to rid off the acid .

(2) Deodorization:Used to rid off the fetid smell/odour of oil by steam understand of high temperature.

(3) Soap feet vessel:Used to refine the oil sediment from oil refining,to get some oil from oil sediment .

(4) Hot & Alkali water tank:Used to produce hot water heated by the steams ,also alkali water from the alkali dis-voling tank,for adding into the oil refining.

palm fruit/bunch → sterilization → threshing → press → clarification → purification →CPO→decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

1. Palm fruit reception:

Transport FFB to reception station, flow to the scraper conveyer, conveyed to sterilizing station.

2. Sterilizaiton:

FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145°C.

3.Threshing:

After sterilizing, fruit bunch transported to thresh machine, separate palm fruit and empty fruit bunch.

4.Digesting:

Before press palm fruit, should be crushed separated pulp and kernel.

5.Oil press:

After crushing and digesting, the maxture of palm fruit and kernel fall into special palm oil presser

6.Clarification:

Filter the oil and use centrifuge to separate oil and impurities.

7.Kernel recovery:

After press, the kernel and cake will be transported to kernel recovery station. Separating nut and shell, then go to kernel oil press.

8. CPO Refining Processes

De-mixed,degumming, dehydration, deacidification, decolorzation, dewaxing and deodorization.

(1) Degumming :Usded to neutrilizing ,and water washing,to rid off the acid .

(2) Deodorization:Used to rid off the fetid smell/odour of oil by steam understand of high temperature.

(3) Soap feet vessel:Used to refine the oil sediment from oil refining,to get some oil from oil sediment .

(4) Hot & Alkali water tank:Used to produce hot water heated by the steams ,also alkali water from the alkali dis-voling tank,for adding into the oil refining.